Dowel screws are versatile fasteners that have a wide range of applications in woodworking and DIY projects. Whether you’re a seasoned craftsman or a DIY enthusiast, understanding how to use dowel screws can greatly enhance your project outcomes. In this guide, we’ll walk you through everything you need to know about using dowel screws effectively. From the basics to advanced techniques, you’ll gain the knowledge and confidence to tackle various projects with ease.

Understanding Dowel Screws

Definition of Dowel Screws

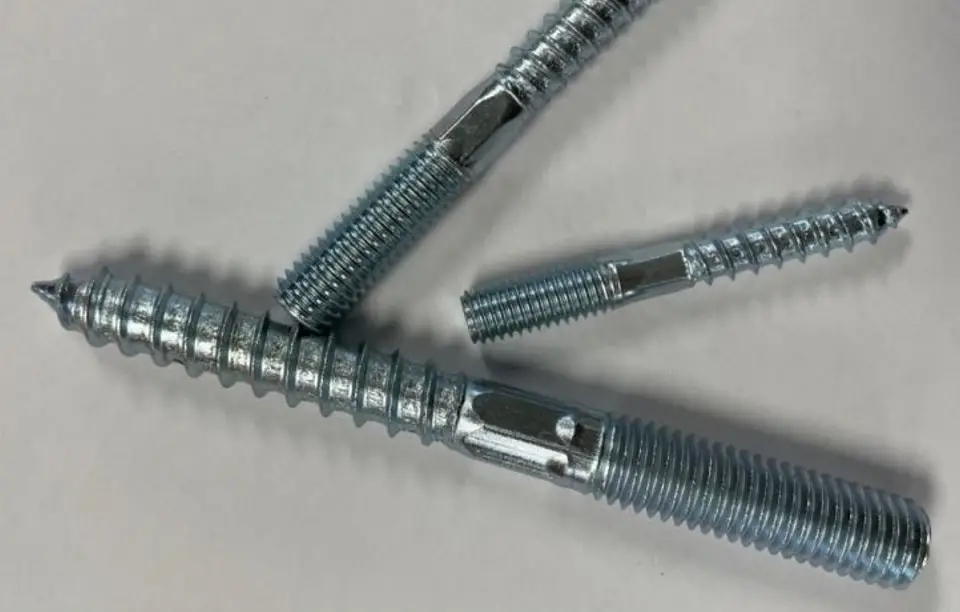

To embark on a journey of mastering the art of using dowel screws, it’s crucial to begin with a clear understanding of what these remarkable fasteners are. At its core, a dowel screw can be described as a unique type of screw with threads at both ends, effectively resembling two screws fused. One end features a wood screw, typically pointed and self-tapping, while the other end boasts a machine screw, complete with a flat or round head and a blunt tip. This dual-threaded design is what sets dowel screws apart from conventional screws and makes them incredibly versatile.

Different Types of Dowel Screws

Dowel screws come in various types and sizes, each tailored to suit specific applications and materials. To navigate the world of dowel screws effectively, it’s essential to be acquainted with the primary categories:

- Wood Dowel Screws: These variants are primarily designed for use in woodworking projects. They typically feature wood threads on one end, making them ideal for joining wooden components.

- Metal Dowel Screws: As the name suggests, metal dowel screws are engineered for use in metalworking applications. They possess machine threads on one end, making them suitable for connecting metal parts securely.

Applications and Industries Where Dowel Screws Are Commonly Used

Dowel screws find their utility across a wide spectrum of applications and industries. Some common scenarios where these versatile fasteners come into play include:

- Cabinetry and Furniture: Dowel screws are extensively used in assembling cabinets, tables, chairs, and other pieces of furniture, ensuring sturdy and durable joints.

- Staircase Construction: They play a pivotal role in constructing stable and reliable staircases by securely attaching balusters and handrails.

- Woodworking Projects: From crafting intricate woodwork to building bookshelves and wooden structures, dowel screws are a trusted choice among woodworkers.

- Metal Fabrication: In the world of metalwork, dowel screws facilitate the assembly of metal components, providing strength and stability.

Advantages and Disadvantages of Using Dowel Screws

Before incorporating dowel screws into your projects, it’s essential to weigh their advantages and disadvantages:

Advantages:

- Strong and Reliable: Dowel screws create robust connections, ensuring your projects withstand the test of time.

- Versatile: They can be used in various materials, including wood, metal, and plastic, making them adaptable for diverse applications.

- Invisible Joints: Dowel screws can create hidden joints, enhancing the aesthetic appeal of your projects.

Disadvantages:

- Precision Required: Proper installation demands precision in drilling and alignment, which can be challenging for beginners.

- Limited Load-Bearing: While sturdy, dowel screws may not be suitable for extremely heavy loads, and alternative fasteners may be necessary.

Understanding these fundamental aspects of dowel screws is the first step towards mastering their usage effectively.

How to Use Dowel Screws

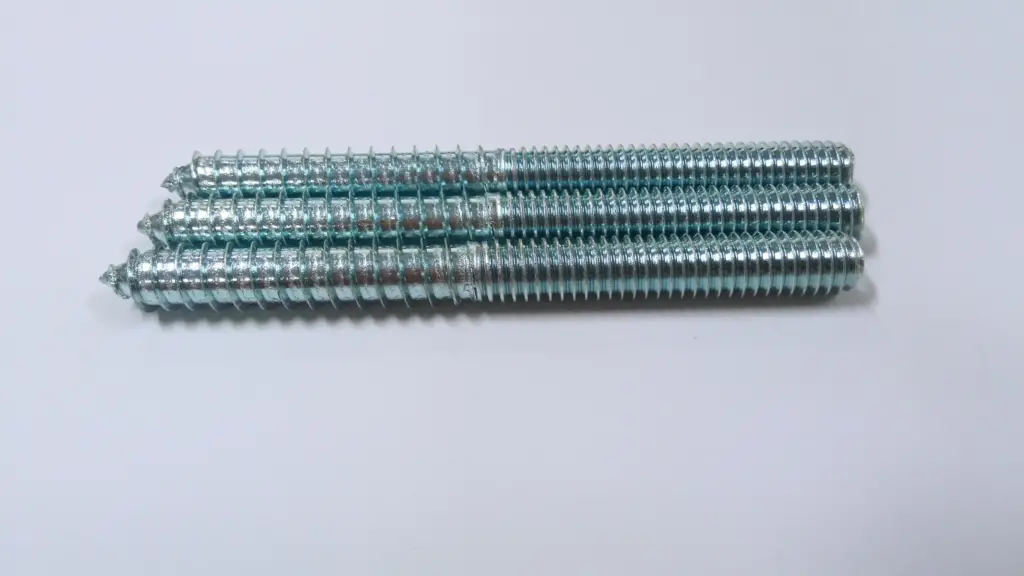

Dowel screws are specialized fasteners with threads on both ends, designed to be screwed into two separate pieces of wood, creating a strong and permanent connection. To use dowel screws effectively, follow these steps:

Step 1: Gather Your Materials

Before you begin, make sure you have the following materials and tools:

- Dowel screws

- Drill and drill bits

- Screwdriver or wrench

- Measuring tape

- Pencil

- Wood glue

- Sandpaper

Step 2: Mark Your Drilling Points

Measure and mark the drilling points on the two pieces of wood you want to join. Ensure that the marks align correctly, as precise measurements are crucial for a secure connection.

Step 3: Drill Pilot Holes

Using an appropriately sized drill bit, create pilot holes at the marked points on both pieces of wood. Pilot holes help prevent splitting and ensure a smoother insertion of the dowel screws.

Step 4: Apply Wood Glue

Apply a generous amount of wood glue to one end of the dowel screw. This will enhance the bond and make the joint even stronger.

Step 5: Insert Dowel Screws

With the wood glue applied, insert one end of the dowel screw into the pilot hole in the first piece of wood. Use a screwdriver or wrench to turn the dowel screw clockwise until it’s securely in place.

Step 6: Join the Second Piece

Repeat the process by inserting the other end of the dowel screw into the pilot hole in the second piece of wood. Again, use a screwdriver or wrench to tighten it clockwise until the pieces are firmly connected.

Step 7: Sand and Finish

Once the joint is secure, sand any rough edges and apply a finish or paint as desired to complete your project.

Maintenance and Care

Ensuring the Longevity of Your Project

While dowel screws create durable and reliable connections, proper maintenance and care are essential to ensure the longevity of your projects. Here are some key steps to consider:

- Regular Cleaning: Depending on the environment and material, dust, dirt, and debris can accumulate around the dowel screw joints. Periodically clean the joints to prevent these contaminants from causing issues.

- Inspect for Wear: Check your projects for any signs of wear or stress on the dowel screw joints. If you notice any problems, address them promptly to prevent further damage.

- Finish Protection: If your project involves wooden surfaces, consider applying a protective finish to shield the wood and dowel screw connections from moisture, UV rays, and other potential sources of damage.

Periodic Checks and Adjustments

To maintain the integrity of your projects, it’s crucial to perform periodic checks and adjustments:

- Alignment: Ensure that the dowel screw connections remain properly aligned. Over time, shifts or movements in the materials may affect the alignment, potentially compromising the joint’s strength.

- Tightness: Check the tightness of dowel screws regularly. Wood may expand or contract due to changes in humidity, affecting the screw’s grip. Tighten the screws as needed to maintain a secure connection.

- Stability: Test the stability of the joints by applying gentle pressure or stress. If you detect any wobbling or looseness, it’s important to address it promptly to prevent further damage.

Replacing Damaged Dowel Screws

In some cases, despite your best efforts, dowel screws may become damaged or compromised. When this happens, it’s essential to know how to replace them:

- Identification: Identify the damaged dowel screw and carefully remove it from the joint using appropriate tools, such as pliers or a screwdriver.

- Matching Replacement: Select a replacement dowel screw that matches the size and type of the original. Ensure it fits snugly into the hole without any play.

- Reinstallation: Carefully insert the replacement dowel screw into the hole, ensuring that it aligns correctly with the mating piece. Secure it in place by turning it clockwise or counterclockwise, depending on the thread direction.

- Testing: After replacing the damaged dowel screw, test the joint’s stability and alignment to ensure it meets the project’s requirements.

By following these maintenance and care guidelines, you can prolong the life of your projects and keep them in optimal condition. Proper attention to detail ensures that the dowel screw connections remain strong and reliable, providing the longevity and performance you expect from your craftsmanship.

Frequently Asked Questions

How strong are dowel screw connections?

Dowel screw connections are incredibly strong and durable, making them suitable for a wide range of applications. The strength of the joint depends on factors such as the size of the dowel screw and the quality of the wood.

Can dowel screws be used outdoors?

While dowel screws can be used outdoors, it’s essential to choose the right type of wood and apply weather-resistant finishes or coatings to protect the joint from the elements.

Are dowel screws suitable for furniture assembly?

Yes, dowel screws are commonly used in furniture assembly. They provide a strong and reliable way to join wooden components, ensuring the stability and longevity of the furniture.

Can I remove dowel screws once they are installed?

Dowel screws are designed for permanent connections, and removing them can be challenging. It’s best to plan your project carefully to avoid the need for removal.

What are some creative applications of dowel screws?

Dowel screws are versatile and can be used for creative projects such as building custom shelving units, wooden sculptures, or even repairing antique furniture.

Are dowel screws suitable for DIY beginners?

While dowel screws are relatively easy to use, beginners should practice on scrap wood before attempting more significant projects to ensure a secure and professional-looking joint.

Conclusion

Knowing how to use dowel screws can significantly expand your woodworking and DIY capabilities. By following the steps outlined in this guide and considering the FAQs, you’ll be well-equipped to tackle various projects with confidence. Dowel screws offer a reliable and sturdy way to join wooden pieces, making them an essential tool for any DIY enthusiast or craftsman.