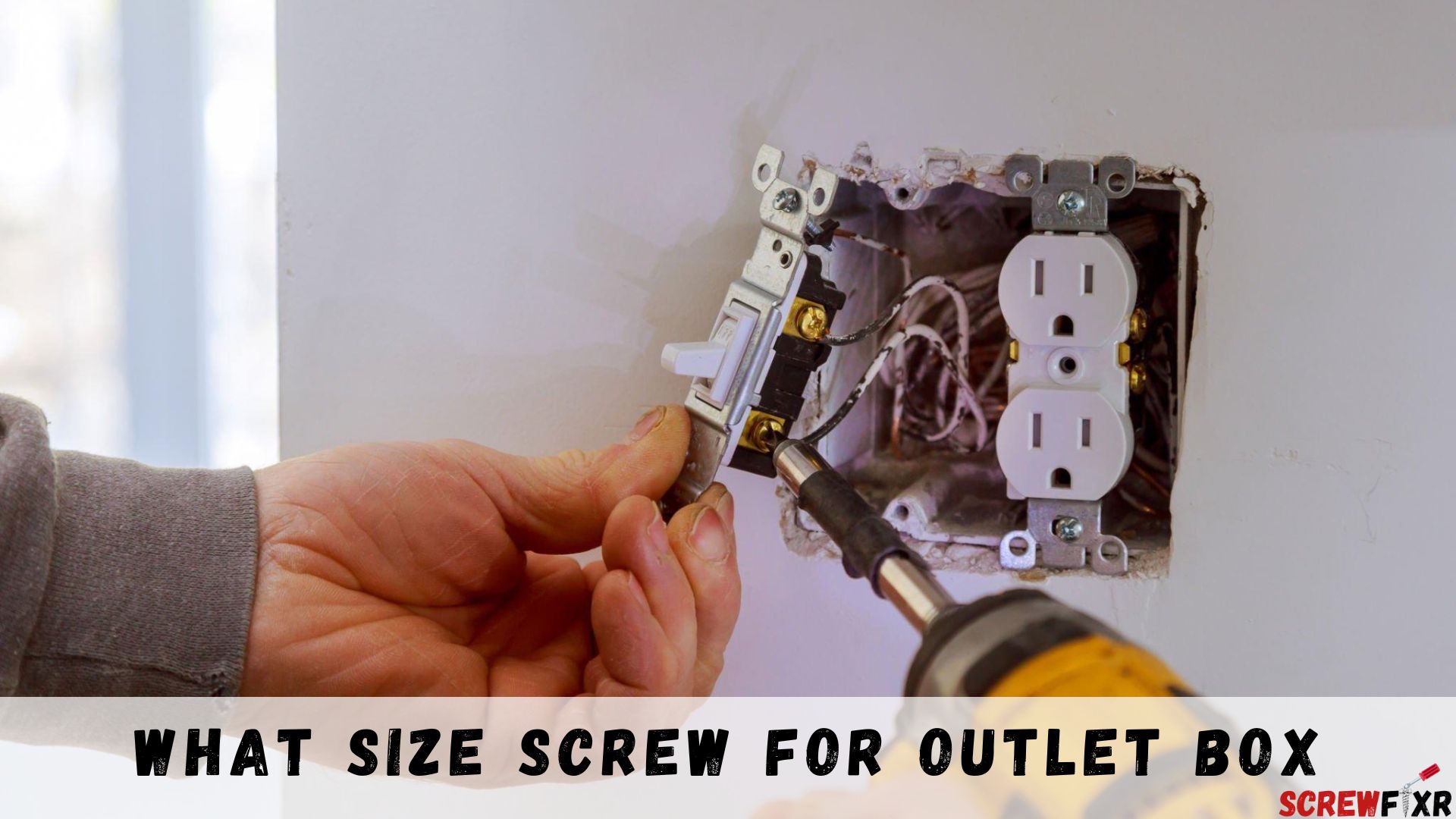

When it comes to electrical installations, even the smallest details matter. One such detail is choosing the correct size screws for outlet boxes. You might think it’s a minor concern, but using the wrong size screw can lead to safety hazards and installation issues. In this comprehensive guide, we’ll delve into the world of outlet box screws, providing you with all the information you need to make the right choice about what size screw for outlet box.

Understanding the Basics of Screw Sizes

Explanation of screw sizing system

Screw sizes are typically indicated using a standardized system that includes a number and sometimes a letter or symbol. The most common screw sizing system in the United States is the Unified Thread Standard (UTS). UTS uses a number system to indicate the diameter and pitch (the distance between threads) of the screw.

For example, a screw labeled #6-32 indicates that it has a diameter of 0.138 inches (6/64 inches) and a pitch of 32 threads per inch. The larger the number, the larger the screw’s diameter. The pitch number represents the number of threads per inch.

Other symbols or letters may be used to provide additional information about the screw, such as the type of head or drive style. For example, a screw labeled as “PH” would indicate it has a Phillips head.

It’s important to note that different types of screws may have different sizing systems. For instance, machine screws typically use a different sizing system compared to wood screws or self-drilling screws. It’s essential to familiarize yourself with the specific sizing system relevant to the type of screw you are using.

Common screw sizes for outlet boxes: #6 and #8

When it comes to outlet boxes, two commonly used screw sizes are #6 and #8. These sizes refer to the diameter of the screw and are typically suitable for securing outlet boxes to electrical junction boxes or mounting brackets.

- #6 screw: A #6 screw has a diameter of approximately 0.138 inches (6/64 inches) and is commonly used for smaller electrical devices or light-duty applications. It is suitable for securing standard plastic outlet boxes or light fixtures.

- #8 screw: A #8 screw has a slightly larger diameter of approximately 0.164 inches (8/64 inches). It is commonly used for securing heavier electrical devices or for applications that require a stronger hold. #8 screws are often used for securing metal outlet boxes or larger electrical fixtures.

It’s important to note that the specific screw size required for your outlet box may vary depending on the manufacturer’s recommendations and the specific requirements of your electrical installation. Always refer to the manufacturer’s instructions or consult with a professional electrician to ensure you are using the appropriate screw size for your specific application.

What Size Screw for Outlet Box – Importance of choosing the right size for a secure fit

Choosing the right screw size for outlet boxes is crucial for ensuring a secure fit. A properly sized screw ensures that the outlet box is securely fastened to the wall or surface, minimizing the risk of any potential hazards. Here’s why choosing the right size is important:

- Safety: Loose or inadequate connections between the outlet box and the wall can lead to electrical hazards, including electrical arcing, overheating, and even fires. Using the correct screw size helps maintain a secure connection, reducing the risk of these hazards.

- Stability: The right screw size ensures a tight fit between the outlet box and the electrical device or fixture being installed. This secure connection prevents any wobbling or movement, providing stability and reducing the chances of short circuits or electrical failures.

- Compliance: Electrical installations are subject to codes and regulations to ensure safety and uniformity. By choosing the appropriate screw size, you comply with these standards, avoiding penalties, failed inspections, and legal consequences.

- Proper grounding and continuity: A secure connection between the outlet box and the electrical device helps maintain proper grounding and electrical continuity. This is essential for the safe and efficient operation of the electrical system.

In summary, choosing the right screw size for outlet boxes is vital for safety, stability, compliance, and proper electrical functioning. It is always recommended to consult the manufacturer’s instructions or seek professional advice to ensure you are using the correct screw size for your specific electrical installation.

Types of Screws for Outlet Boxes

Machine Screws

- Description and purpose: Machine screws are typically used for applications that require a secure and precise fastening. They are threaded screws that are designed to be used with a corresponding nut or threaded hole. Machine screws have a uniform diameter along their entire length and are available in various head types, such as flat head, round head, or pan head. They are typically made of metal and come in a range of sizes.

- Usage with threaded holes in outlet boxes: Machine screws are commonly used to secure outlet boxes to junction boxes or mounting brackets that have pre-drilled and threaded holes. These screws provide a secure and reliable connection, ensuring that the outlet box remains firmly attached to the surface. When using machine screws with outlet boxes, it’s important to select the appropriate size and length to ensure a proper fit and sufficient engagement with the threaded hole.

Wood Screws

- Description and purpose: Wood screws are designed specifically for use with wood and other soft materials. They have a tapered, pointed end and a threaded shaft that is wider in diameter than the screw’s head. Wood screws come in various head types, such as flat head, round head, or countersunk head. They are typically made of steel or brass and are available in different sizes.

- Usage when securing outlet boxes to wooden surfaces: When securing outlet boxes to wooden surfaces, wood screws are commonly used. These screws are driven directly into the wood, creating a strong and secure connection. Wood screws are self-tapping, meaning they create their threads as they are driven into the wood. They provide excellent holding power and are suitable for both light-duty and heavy-duty applications. When using wood screws with outlet boxes, it’s important to select the appropriate size and length to ensure a proper fit and sufficient penetration into the wood.

It’s important to note that the specific type and size of screws required for outlet boxes may vary depending on the manufacturer’s recommendations and the specific requirements of your electrical installation.

Factors to Consider When Choosing Screw Sizes

Box Material

- Different screw requirements for metal, plastic, or fiberglass boxes: The material of the box will impact the type of screws needed for secure installation. Metal boxes typically require machine screws, as they have pre-drilled and threaded holes. Plastic or fiberglass boxes may require self-tapping screws, such as wood screws, as they do not have pre-drilled holes.

Load Capacity

- Importance of considering weight and load capacity: When choosing screws for securing fixtures to outlet boxes, it’s important to consider the weight and load capacity of the fixture. Heavier fixtures will require screws that can support the weight without compromising the integrity of the installation.

- Choosing longer or stronger screws for heavier fixtures: For heavier fixtures, longer or stronger screws may be necessary to provide adequate support. Longer screws will provide a deeper and more secure attachment to the outlet box, while stronger screws, such as those with a higher tensile strength, can handle heavier loads.

Electrical Code Compliance

- Need to adhere to local electrical codes and regulations: When selecting screws for outlet boxes, it’s crucial to ensure compliance with local electrical codes and regulations. These codes may specify the type of screws, their size, and other requirements for safe and proper installation.

- Consultation with a licensed electrician or reference to building codes: It is recommended to consult with a licensed electrician or refer to the local building codes to determine the specific screw requirements for outlet boxes in your area. Electricians are familiar with the local regulations and can guide the appropriate screws to use for electrical installations.

It’s important to note that the specific screw requirements may vary depending on the specific application and local regulations. Always follow the manufacturer’s instructions and consult with a professional when in doubt to ensure a safe and code-compliant installation.

Installation Tips for Outlet Box Screws

Proper Tools and Equipment

- Use appropriate screwdrivers or drill bits: When installing outlet box screws, it’s important to use the appropriate tools and equipment. Choose a screwdriver or drill bit that matches the screw head, ensuring a proper fit and reducing the risk of stripping or damaging the screw.

Secure Fastening

- Tightening screws securely without overtightening: It’s crucial to tighten outlet box screws securely to ensure a stable and secure installation. However, it’s equally important not to overtighten the screws, as this can damage the box or strip the threads. Use a steady and controlled force to tighten the screws until they are snug but not excessively tight.

Securing to Studs

- Using longer screws for added stability when securing studs: When attaching outlet boxes to wall studs, using longer screws can provide added stability. Longer screws will penetrate deeper into the stud, creating a stronger connection and reducing the risk of the box becoming loose over time.

Remember to refer to the manufacturer’s instructions and consult with a professional if you have any doubts or specific requirements for your installation.

Frequently Asked Questions

Can I use any screws for an outlet box?

No, it’s essential to use the correct screw size and type for your outlet box to ensure a safe and secure installation. Using the wrong screws can lead to electrical hazards and structural issues.

What if I don’t know the type of outlet box I have?

If you’re unsure about the type of outlet box you have, consult a professional electrician. They can assess your setup and recommend the appropriate screws for your specific needs.

Can I reuse screws from an old outlet box?

It’s generally not recommended to reuse screws from an old outlet box. Over time, screws can weaken, corrode, or become damaged, compromising the safety and stability of the installation. It’s best to use new, high-quality screws for any electrical work.

Are stainless steel screws a good choice for outlet boxes?

Stainless steel screws are a suitable choice for outlet boxes, especially in areas prone to moisture or corrosion. They offer excellent durability and resistance to rust, ensuring the longevity of your electrical installation.

What if I accidentally strip a screw hole in the outlet box?

If you strip a screw hole in the outlet box, you can use a larger screw or a wall anchor to secure it. However, it’s crucial to address this issue promptly to maintain the integrity of the installation.

Is it safe to overtighten outlet box screws?

No, over-tightening screws can damage the outlet box, wall material, or wires inside. Tighten the screws until they are snug but not excessively tight to avoid any issues.

Conclusion

Selecting the right screw size for your outlet box might seem like a small detail, but it’s a crucial step in ensuring the safety and stability of your electrical installations. Always consider the type of wall, box material, and load capacity before making your choice. By following these guidelines, you’ll be well on your way to a secure and long-lasting installation.